| << Chapter < Page | Chapter >> Page > |

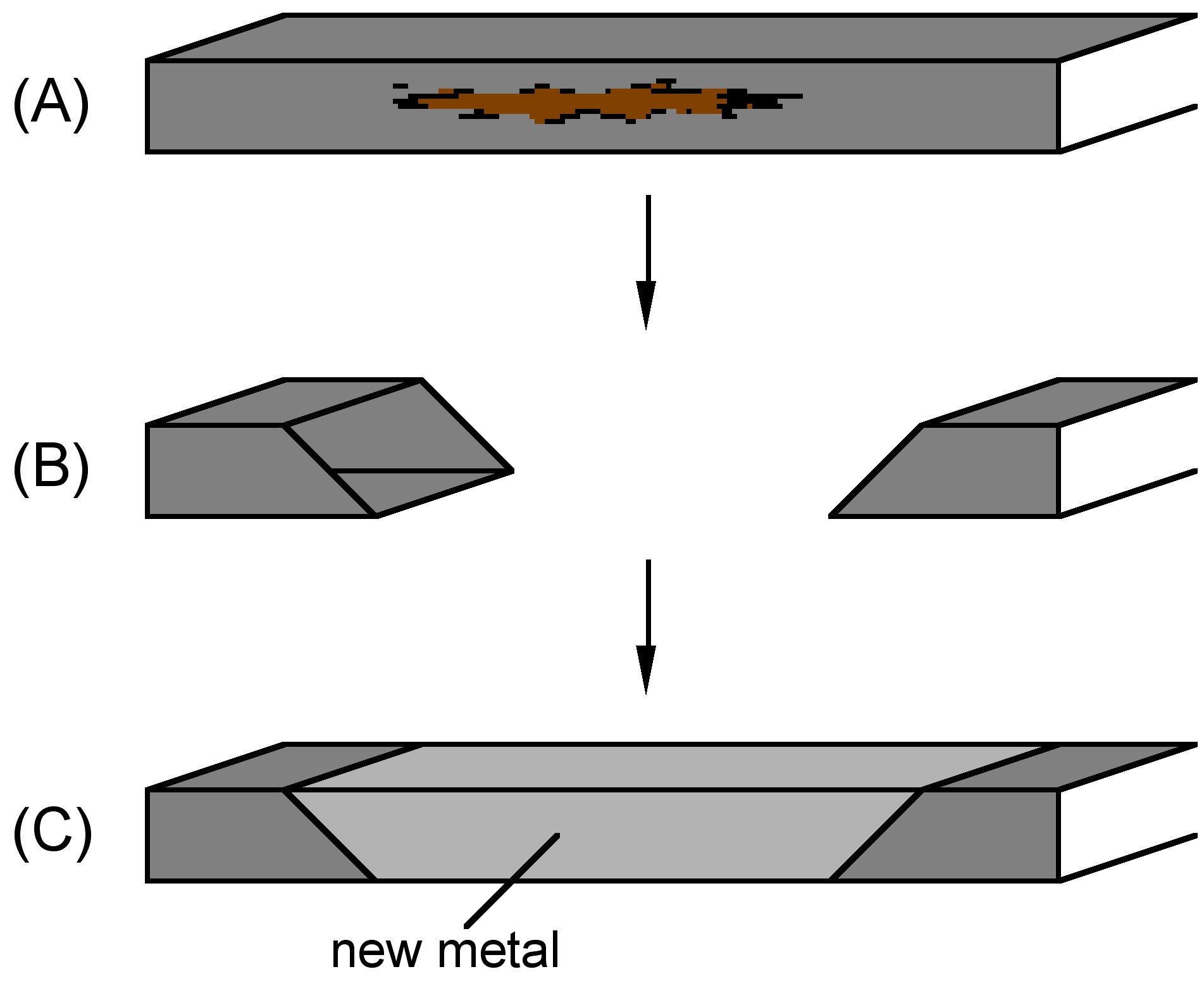

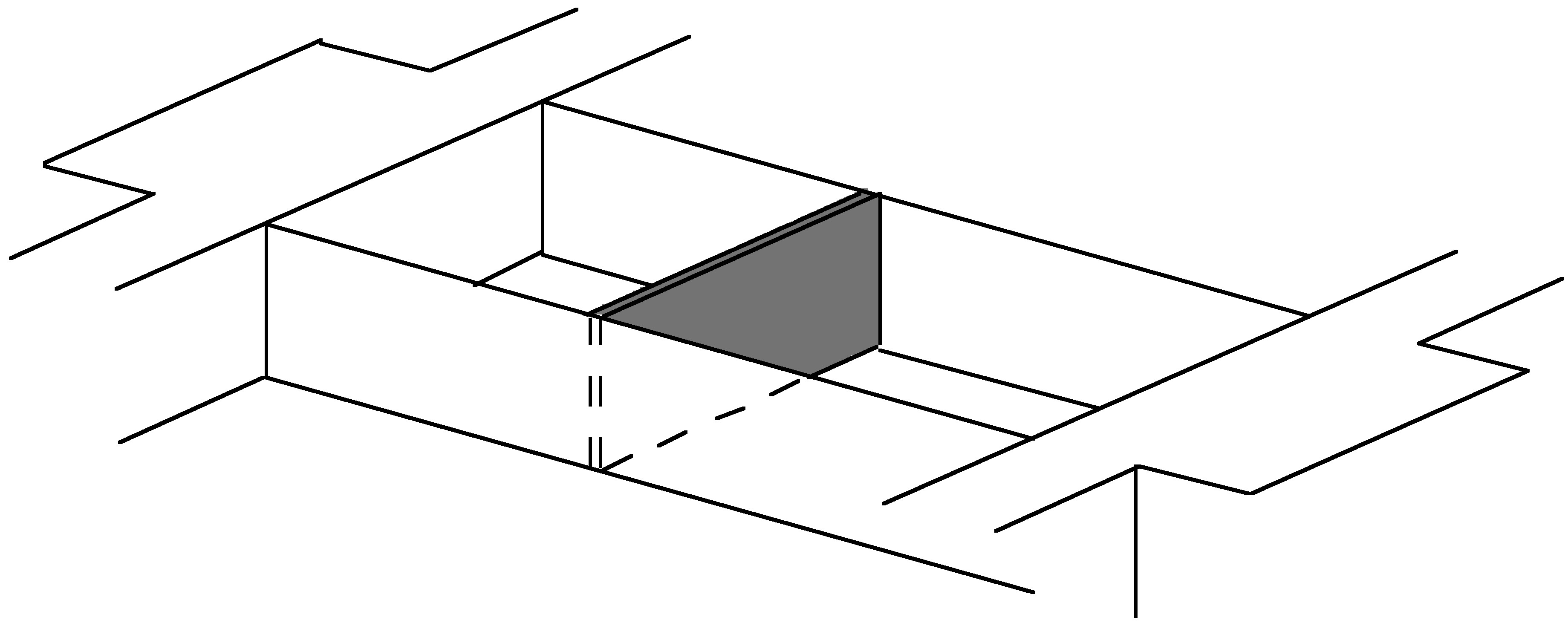

The front box section is almost completely corroded and needs to be replaced. In addition, this is a good time for it to be strengthened so that it can be used as a front jack point. The complete lower part of the box was cut away and a replacement section made from 1 / 8 ” steel plate. Before the lower section is welded in place a brace is welded to strength the box ( [link] ). Once the lower section is welded in place the sides are straightened and then welded to the new metal ( [link] and [link] ).

On the upper side of the box section the seams were bronzed to ensure that no water ingress could occur and cause a repeat of the corrosion that was present.

As shown in [link] one of the four bolts holding the steering rack clamps had sheered-off. Given that the nut is welded to the lower side of the mount, and it was found difficult to remove the bolt or replace that one nut, it was decided to replace the whole top of the bracket along with new nuts ( [link] ).

At the rear of the chassis the inner seat belt and axle locating link are attached to a removable brace. The points where this is bolted to the cross member were strengthened ( [link] ).

The original side panels were made from thin steel, and since they were damaged by the fire ( [link] ) it was necessary to replace the panels. However, it was decided to upgrade the thickness of the panel for added strength.

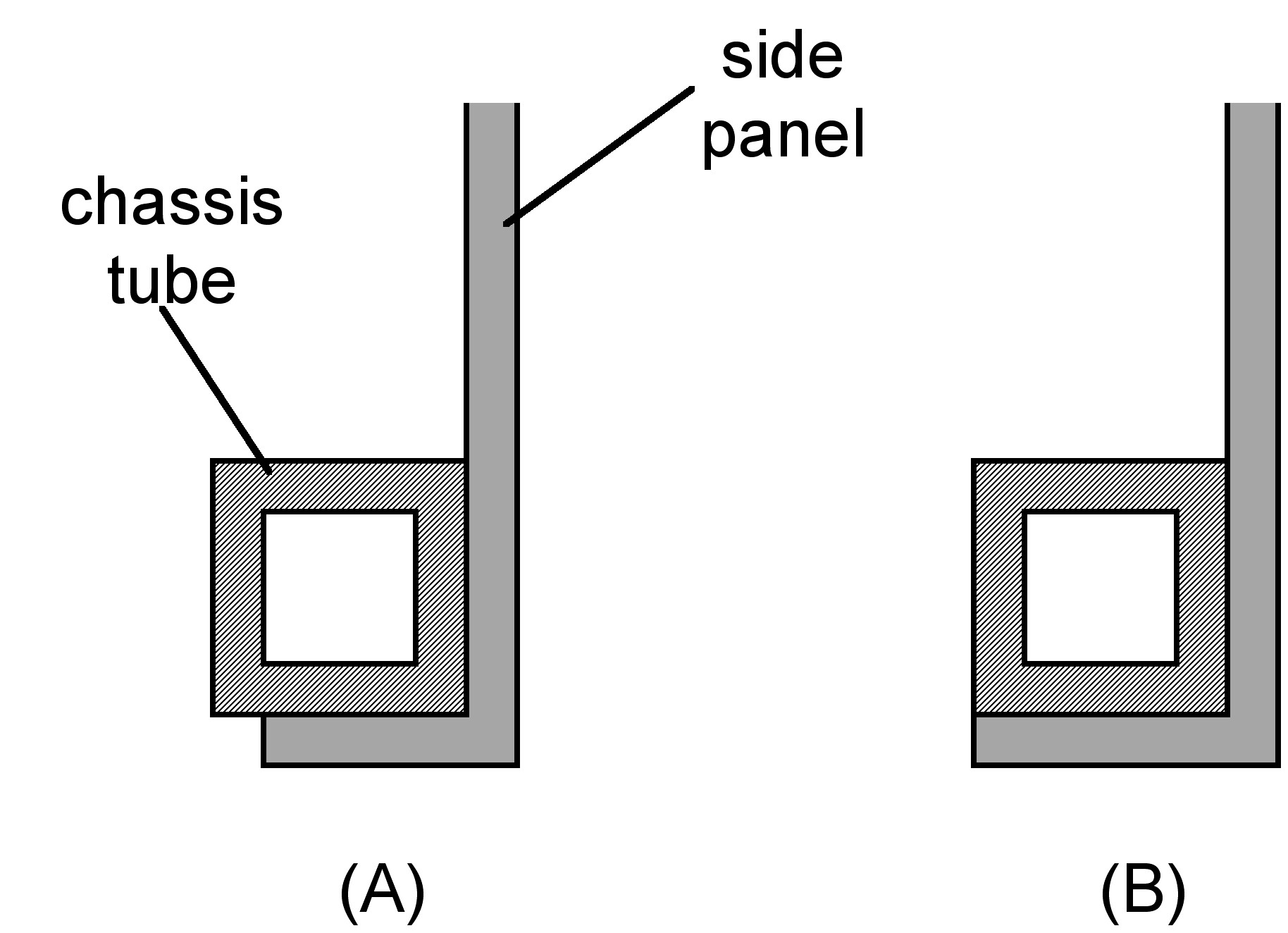

New panels were cut from 18 gauge steel using the original panels as templates. The new panels were welded to the repaired frame by drilling a 3 / 16 ” hole in the panel and TIG welding through the hole. This resulted in a spot-welded look, but with a greater strength. The finished panels are shown in [link] - [link] . The original panels were sized such that when the edges were folded over the chassis rail, they did not meet the edge ( [link] A). The new panels were sized such that the edges matched ( [link] B). Prior to welding the side panels, the chassis and panels were sprayed with weld-through primer to ensure that corrosion does not occur under the powder coat.

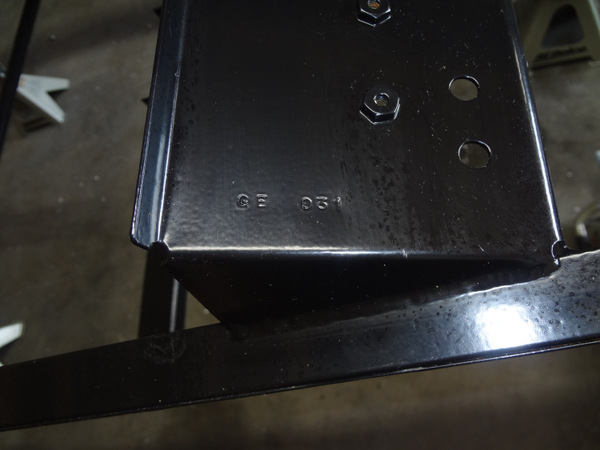

Once the chassis frame was repaired and the new side panels were welded in place the whole chassis was cleaned by media blasting and powder coated semi gloss black ( [link] - [link] ). Powder coating was performed by Custom Coatings (Cypress, TX).

One of the advantages of media blasting and powder coating is that the original frame number became visible ( [link] ). The number GE-031 indicates that the chassis was produced by Griston Engineering.

Notification Switch

Would you like to follow the 'Lotus seven s4 (type 60): design, restoration, and maintenance' conversation and receive update notifications?