| << Chapter < Page | Chapter >> Page > |

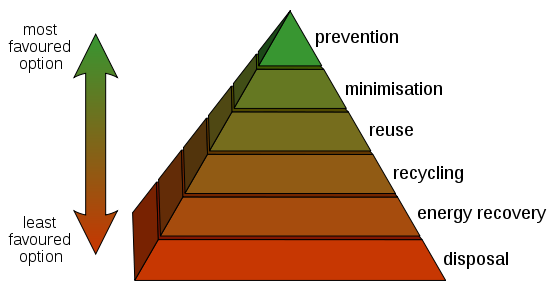

The long-recognized hierarchy of management of wastes, in order of preference consists of prevention, minimization, recycling and reuse , biological treatment , incineration, and landfill disposal (see Figure Hierarchy of Waste Management ).

The ideal waste management alternative is to prevent waste generation in the first place. Hence, waste prevention is a basic goal of all the waste management strategies. Numerous technologies can be employed throughout the manufacturing, use, or post-use portions of product life cycles to eliminate waste and, in turn, reduce or prevent pollution . Some representative strategies include environmentally conscious manufacturing methods that incorporate less hazardous or harmful materials, the use of modern leakage detection systems for material storage, innovative chemical neutralization techniques to reduce reactivity, or water saving technologies that reduce the need for fresh water inputs.

In many cases, wastes cannot be outright eliminated from a variety of processes. However, numerous strategies can be implemented to reduce or minimize waste generation. Waste minimization , or source reduction, refers to the collective strategies of design and fabrication of products or services that minimize the amount of generated waste and/or reduce the toxicity of the resultant waste. Often these efforts come about from identified trends or specific products that may be causing problems in the waste stream and the subsequent steps taken to halt these problems. In industry, waste can be reduced by reusing materials, using less hazardous substitute materials, or by modifying components of design and processing. Many benefits can be realized by waste minimization or source reduction, including reduced use of natural resources and the reduction of toxicity of wastes.

Waste minimization strategies are extremely common in manufacturing applications; the savings of material use preserves resources but also saves significant manufacturing related costs. Advancements in streamlined packaging reduces material use, increased distribution efficiency reduces fuel consumption and resulting air emissions. Further, engineered building materials can often be designed with specific favorable properties that, when accounted for in overall structural design, can greatly reduce the overall mass and weight of material needed for a given structure. This reduces the need for excess material and reduces the waste associated with component fabrication.

The dry cleaning industry provides an excellent example of product substitution to reduce toxic waste generation. For decades, dry cleaners used tetrachloroethylene, or "perc" as a dry cleaning solvent. Although effective, tetrachloroethylene is a relatively toxic compound. Additionally, it is easily introduced into the environment, where it is highly recalcitrant due to its physical properties. Further, when its degradation occurs, the intermediate daughter products generated are more toxic to human health and the environment.

Notification Switch

Would you like to follow the 'Sustainability: a comprehensive foundation' conversation and receive update notifications?