| << Chapter < Page | Chapter >> Page > |

We now put the wafer in a sputter deposition system. In the sputter system, we coat theentire surface of the wafer with a conductor. An aluminum-silicon alloy is usually used, although other metalsare employed as well.

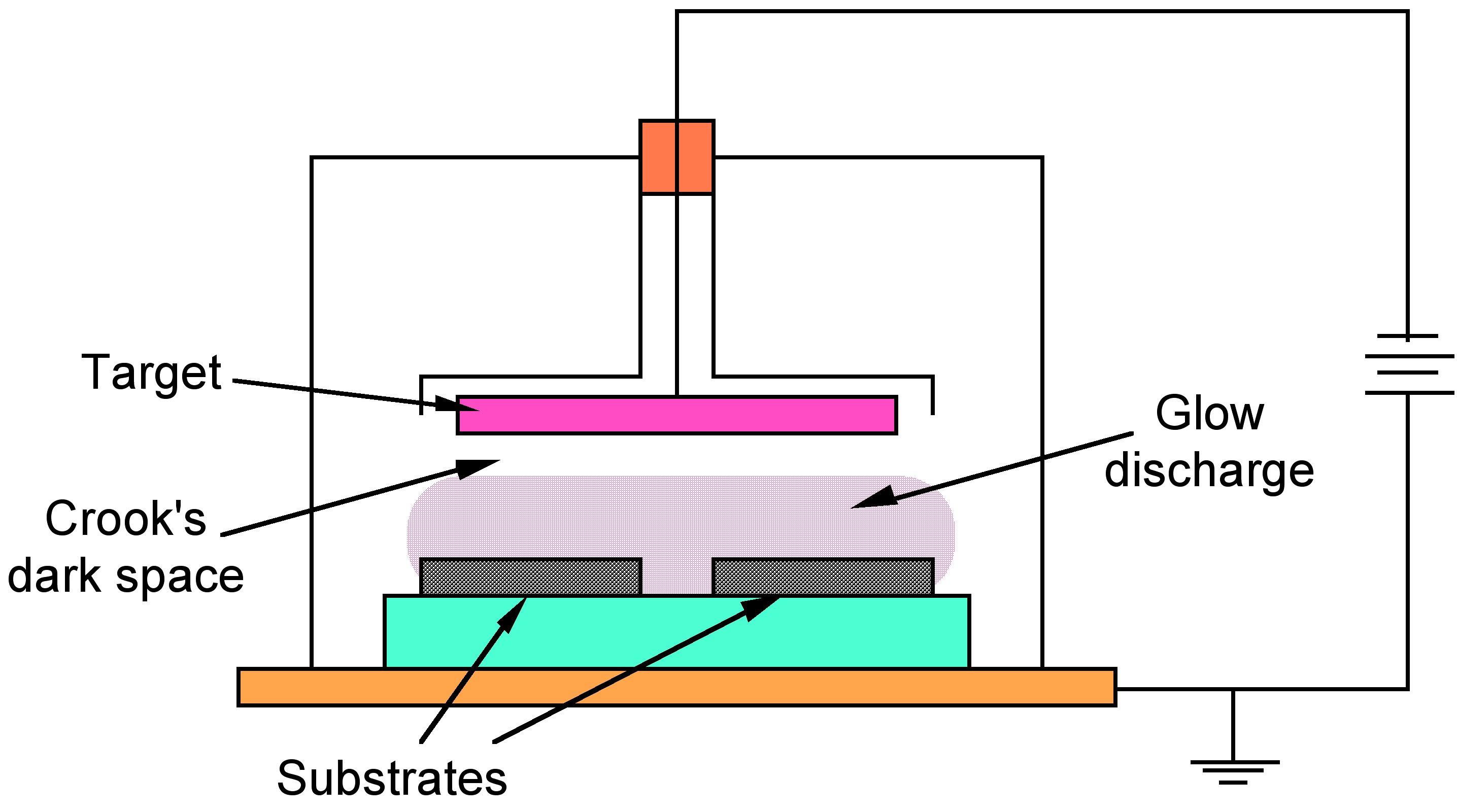

A sputtering system is shown schematically in [link] . A sputtering system is a vacuum chamber, which after it is pumped out, is re-filled with a low-pressureargon gas. A high voltage ionizes the gas, and creates what is known as the Crookes dark space near the cathode,which in our case, consists of a metal target made out of the metal we want to deposit. Almost all of the potential of thehigh-voltage supply appears across the dark space. The glow discharge consists of argon ions and electrons which have beenstripped off of them. Since there are about equal number of ions and electrons, the net charge density is about zero, and henceby Gauss' law, so is the field.

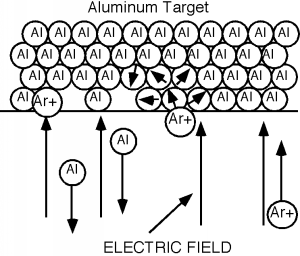

The electric field accelerates the argon atoms which slam into the aluminum target. There is an exchange of momentum, and analuminum atom is ejected from the target ( [link] ) and heads to the silicon wafer, where it sticks, and builds up ametal film [link] .

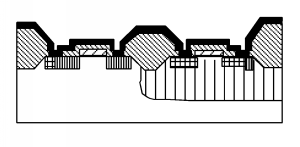

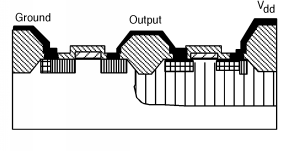

If you look at [link] , you will note that we have seemingly done something pretty stupid. We have wired all of theelements of our CMOS inverter together; but all is not lost. We can do one more photolithographic step, and pattern andetch the aluminum, so we only have it where we need it. This is shown in [link] .

Notification Switch

Would you like to follow the 'Chemistry of electronic materials' conversation and receive update notifications?