| << Chapter < Page | Chapter >> Page > |

Photolithography is one of the most important technology in the production of advanced integrated circuits. It is through photolithography that semiconductor surfaces are patterned and the circuits formed. In order to make extremely small features, on the order of the wavelength of the light, advanced optical techniques are used to transfer a pattern from a mask onto the surface. A polymeric film or resist , is modified by the light and records the information in a process not dissimilar to ordinary photography.

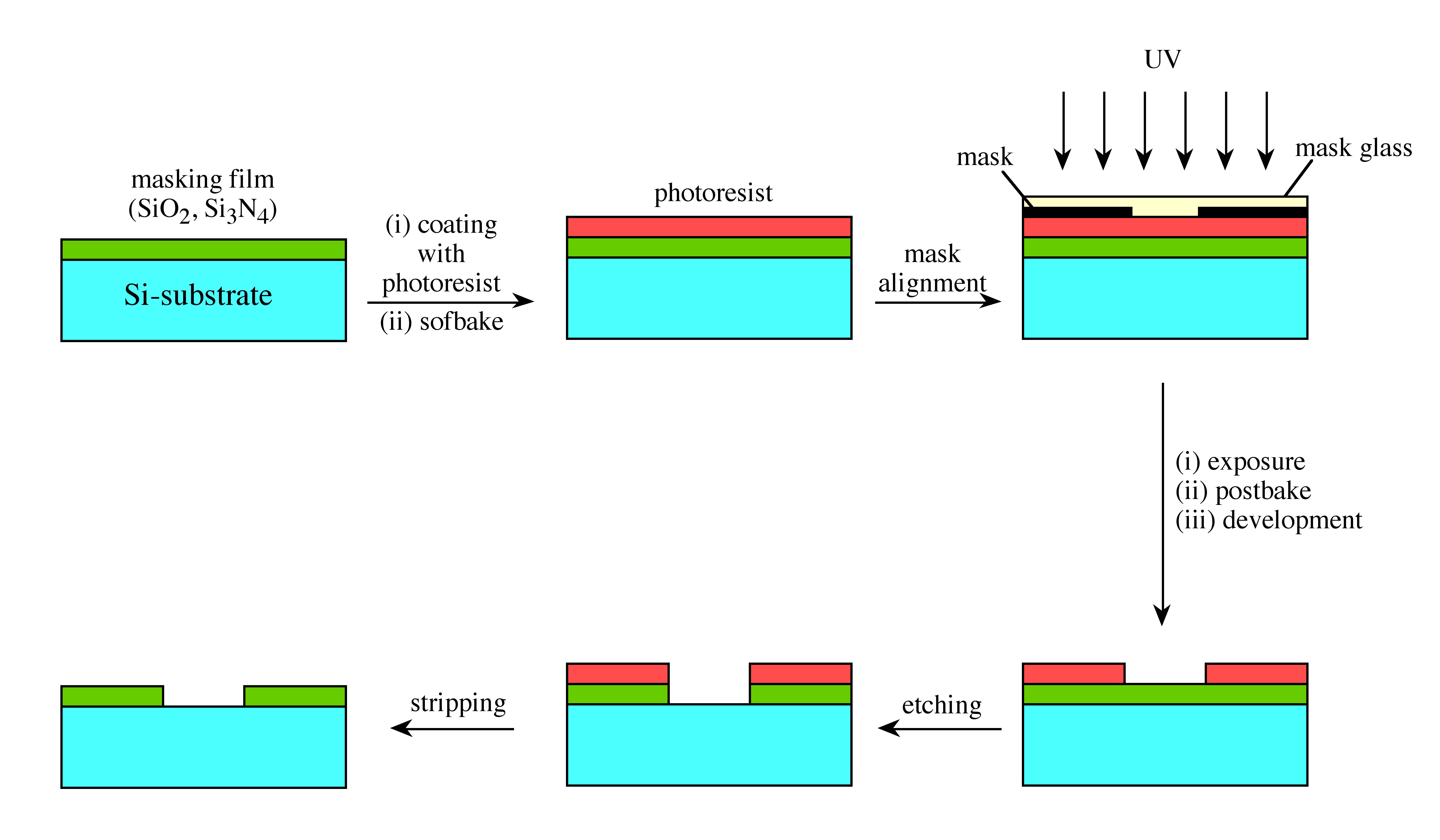

An illustration of the photolithographic process is shown in [link] . The process follows the following basic steps:

In addition to being possibly the most important semiconductor process step, photolithography is also the most expensive technology in semiconductor manufacturing. This expense is the result of two considerations:

This means that not only are photolithography machines the most expensive of semiconductor processing equipment, but more of them are needed in order to maintain throughput.

A semiconductor process technology is often described by a characteristic length known as the critical dimension. The critical dimension (CD) is the smallest feature that needs to be patterned on the surface. The exact definition varies from process to process but is often the channel length of the smallest transistor (typical of a memory chip) or the width of the smallest metal interconnection line (logic chips). This critical dimension is defined by the photolithographic process and is perhaps the most important figure of merit in the manufacture of integrated circuits. Making the critical dimension smaller is the primary focus of improving semiconductor technology for the following reasons:

Notification Switch

Would you like to follow the 'Chemistry of electronic materials' conversation and receive update notifications?