| << Chapter < Page | Chapter >> Page > |

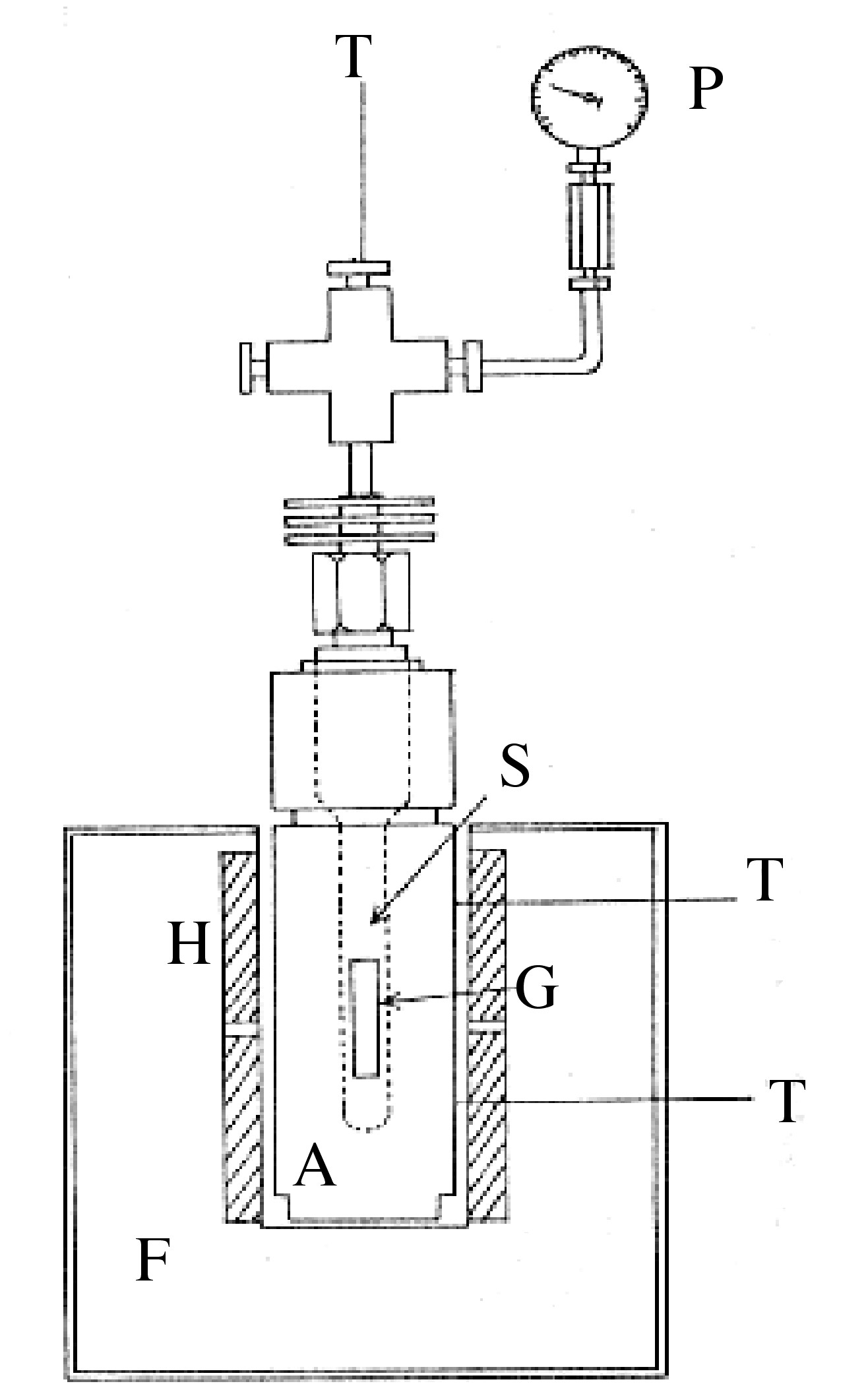

BaBe 2 Si 2 O 7 (barylite) has been known as material with a strong piezoelectricity, however, it can not be obtained by solid-state reaction and CZ technique therefore is not applicable. As an alternative for piezoelectric crystals growth hydrothermal synthesis has been developed. [link] shows the experimental apparatus for the growth of barylite. Eventhough, crystals can be obtained using this technique, high pressure (500 - 1000 bar) and a solvent for the raw materials are required.

While the piezoceramics dominate the single crystal materials in usage, single crystals piezoelectrics continue to make important contributions both in price-conscious consumer market and in performance-driven defense applications. Areas such as frequency stabilized oscillators, surface acoustic wave devices and filters with a wide pass band, are still dominated by single crystals.

Recently, there has been great interest in the deposition of piezoelectric thin films, mainly for microelectronical systems (MEMS) applications; where the goal is to integrate sensors and actuators based on PZT films with Si semiconductor-based signal processing; and for surface acoustic wave (SAW) devices; where the goal is to achieve higher electromechanical coupling coefficient and temperature stability. Piezoelectrical microcantilevers, microactuators, resonators and SAW devices using thin films have been reported.

Several methods have been investigated for PZT thin films. In the metallo-organic thin film deposition, alkoxides are stirred during long periods of time (up to 18 hours). After pyrolisis, PZT amorphous films are formed and then calcination between 400 – 600 °C for 80 hours leads to PZT crystallization (perovskita phase) by a consecutive phase transformation process, which involves a transitional pyrochlore phase.

A hybrid metallorganic decomposition (MOD) route has also been developed to prepare PZT thin films. Lead and titanium acetates and, zirconium acetylacetonate are used. The ferroelectric piezoelectric and dielectric properties indicate that the MOD route provides PZT films of good quality and comparable to literature values. In addition to being simple, MOD has several advantages which include: homogeneity at molecular level and ease composition control.

Metalorganic chemical vapor deposition (MOCVD) has been applied to PZT thin films deposition also. It has been proved that excellent quality PZT films can be grown by using MOCVD, but just recently the control of microstructure the deposition by varying the temperature, Zr to Ti ratio and precursors flow has been studied. Recent progress in PZT films deposition has led to lower temperature growth and it is expected that by lowering the deposition temperature better electrical properties can be achieved. Additionally, novel techniques such as KrF excimer laser ablation and, ion and photo-assisted depositions, have also been used for PZT films synthesis.

Notification Switch

Would you like to follow the 'Chemistry of electronic materials' conversation and receive update notifications?